How strong is China's mold productivity ? It accounts for a third of world output.

Recently, the 19th China International Mold Technology and Equipment Exhibition opened in Shanghai.The reporter learned that in 2018, China's mold consumption was 255.5 billion yuan, accounting for about one third of the world's mold consumption, and mold output value also accounted for more than one third of the world's total mold output value.

According to customs statistics, China's mold export exceeded $5 billion in 2015, and in 2018, China's mold export was $6.085 billion, with a year-on-year growth of 10.84%, accounting for a quarter of the total global mold export, with exports covering about 200 countries and regions around the world.The import value of China's mould was 2.14 billion US dollars, accounting for less than 5% of China's mould consumption value.

Mold is known as the "mother of industry".According to the research of China Mold and Die Industry Association, in 2018, China's mold consumption of 255.5 billion yuan, can support the national 28 trillion yuan of industrial finished products, is an important part of "Made in China", plays a role from the "big power" to the change and improvement of people's life "behind the scenes hero".Take the automobile industry as an example, the mold dependence of automobile manufacturing has exceeded 90%, and more than 95% of the country's mold enterprises are involved in the automobile mold.

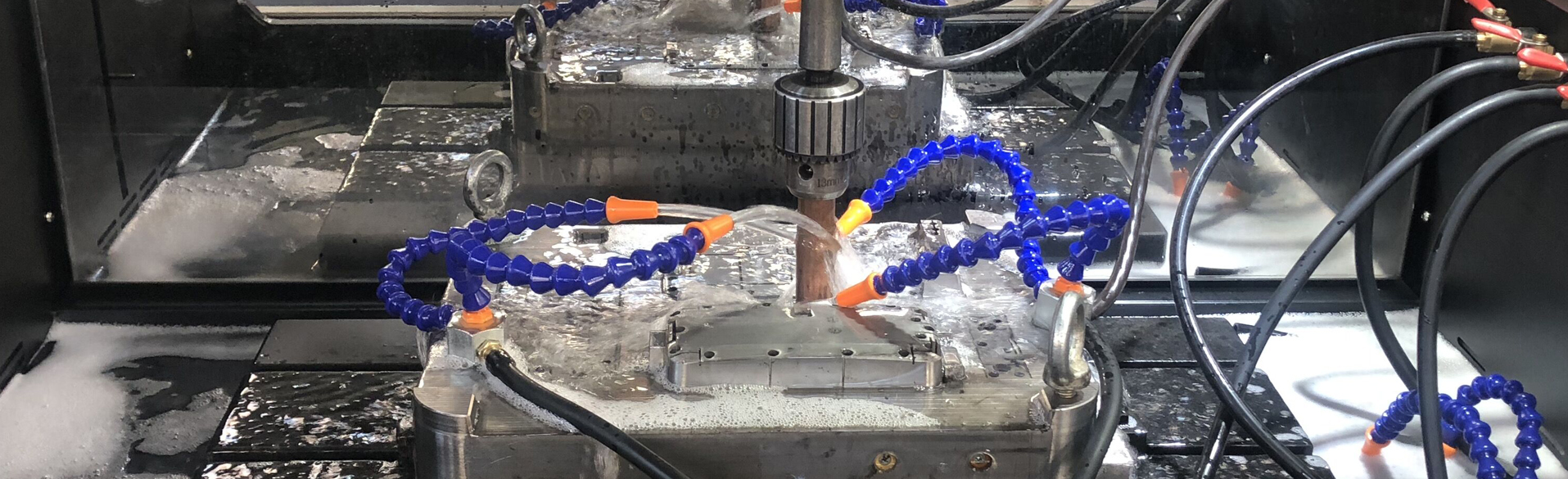

According to the introduction, today's die and mould industry technology innovation driven characteristics are obvious, some die and mould enterprises have shifted from tracking to tracking and running a new stage, a number of enterprises have entered the first international manufacturing square.Refined, automation, information, integration, network, intelligent technology to speed up the industry to improve the quality and efficiency, optimization and upgrading, mold products continue to large, precision, high performance, integration direction, mold processing is also developing to the direction of high precision, high stability, high efficiency.

Copyright © 2009-2021,www.mould-solution.com,All rights reserved copyright © Your website name is not allowed to be copied without permission