In recent years, with the development of Industry 4.0, China's manufacturing industry has been developing more and more rapidly from "manufacturing" to "intelligent manufacturing". 3D printing technology has been widely used in China's manufacturing industry. 3D printers can provide efficient and low-cost support for mold design and manufacturing.Even with the rapid development of 3D printing technology, in some fields, it has gradually begun to subvert mold technology and form a direct competitive relationship with it.

"Compared to 3D printing technology, traditional mold manufacturing requires more steps and processes, and the mold production cycle is longer.When a mold maker introduces a new product, it has to pass rigorous international standards and certification before it can be released to the market, and certification of many components can be time-consuming.This will make the new product in a very unfavorable position in the time to seize the market.The 3D printing injection mold is an efficient solution.This is what the well-known manufacturer Easy Molding does, in their open lab, using 3D printing technology to make injection molds."While it usually takes a few weeks to two months to produce a mold, 3D printing can prototype a mold in a matter of hours, and changes can be made immediately based on test results, according to IME Secretary General David Lo.And then injection out of the final product sample.These product samples can be sent directly for certification, while at this time the traditional mold manufacturing may still be in production, and even before the mold is determined after the latest, 3D printed products have been certified, greatly reducing the development cycle.Only in the mold production cycle, 3D printing technology has had a certain impact on the traditional mold manufacturing.

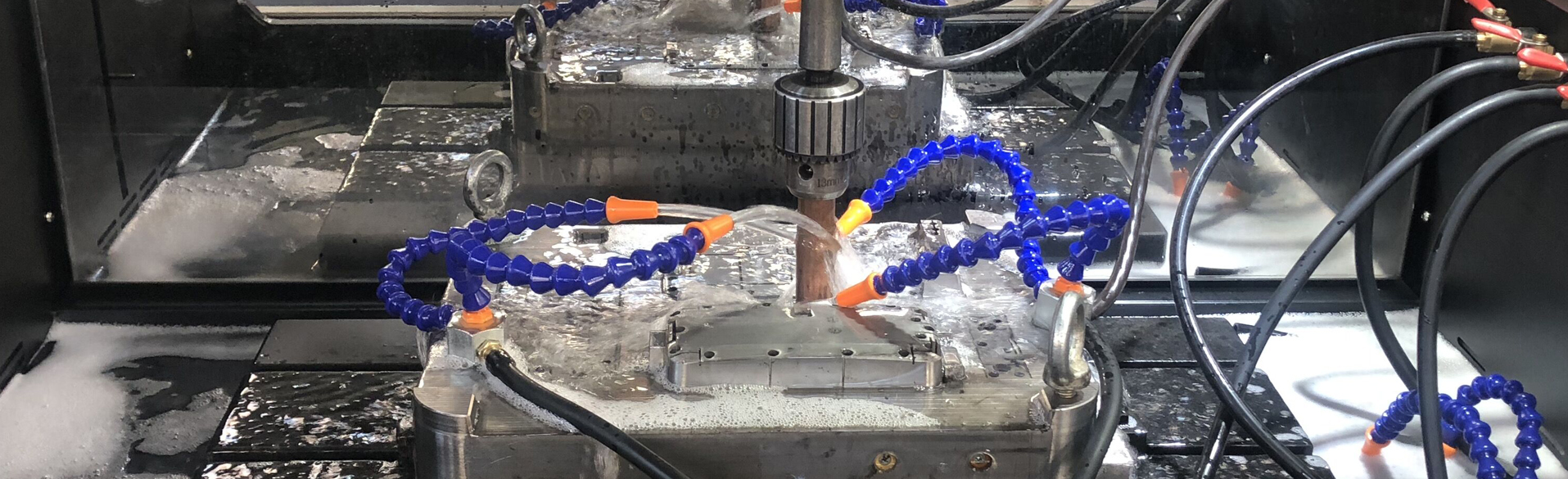

However, experts in the industry said that although 3D printing technology has many advantages such as short production cycle, convenient raw materials and uniform product pressure, 3D printing technology cannot completely replace the traditional mold manufacturing method, because there are still some problems in the manufacturing process of 3D printing technology.For example, 3D printing technology is to process products layer by layer, which will shorten the production cycle of the mold, but at the same time, it will also lead to the step effect on the surface of the mold.Direct-print molds have similar problems, requiring machining or sandblasting to eliminate the tiny, toothed edges.In addition, holes smaller than 1mm must be drilled, larger holes need to be reamed or drilled, and thread features need to be tapped or milling, which greatly reduces the speed advantage of 3D printed molds.

In addition, in product design, the principle and practice of traditional injection mold manufacturing has a history of more than a century, and the industry has a more thorough research on it. For example, the oblique Angle of drawing mold must be greater than or equal to 5 degrees to meet the requirements of most aluminum mold.3D printing moulds for injection plastic parts are challenging, requiring extra care in the number and placement of thimbles for plastic moulds.3D printing moulds (especially high injection temperatures) are somewhat more flexible in terms of increasing cavity wall thickness and reducing pressure.The gate design also varies and tunnel and point gates should be avoided.Direct gate, fan gate, and wing gate should be increased to 3 times normal size.The flow direction of the polymer in the printing mold should be consistent with the 3D printing line to avoid stickiness and high filling caused by low pressure.The cooling system can improve the life of the die to some extent, but it will not significantly reduce the number of cycles of the printed die, because the heat dissipation capacity of the 3D printed die is not as good as that of the aluminum or steel die.

To sum up, 3D printing technology will not completely replace the traditional mold manufacturing industry.Because 3D printing mold in the quality of finished products, product cost and mold design compared with the traditional mold manufacturing, there are still some deficiencies.Moreover, 3D printing is not suitable for mass production. The unit cost of producing 1 piece is basically similar to that of producing 10,000 pieces. Moreover, 3D printing takes a long time.The current 3D printing technology can only be used for mold production with tight requirements of small batch production cycle, and mass production is mainly based on traditional mold manufacturing.

Copyright © 2009-2021,www.mould-solution.com,All rights reserved copyright © Your website name is not allowed to be copied without permission